In the quest for sustainable energy solutions, the role of advanced mechanical components like slewing drives cannot be overstated. These versatile and robust devices are integral to enhancing the efficiency and reliability of renewable energy systems. This blog post explores what slewing drives are and their pivotal role in renewable energy projects, particularly in solar trackers and wind turbines.

SlewPro Blog

Richard Potesta

Recent Posts

Exploring the Versatility of Slewing Drives in Renewable Energy Projects

Topics: slew drive, slewing drive

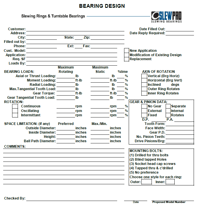

A Guide to Seeking Application Assistance from Slewing Ring Bearing Manufacturers

Slewing ring bearings play a critical role in various industrial applications, providing rotational support for heavy machinery and equipment. When it comes to selecting the right slewing ring bearing for your specific application, seeking assistance from manufacturers is crucial. To ensure the best possible outcome for customers, it's essential to provide manufacturers with comprehensive information about your application. In this blog, we'll outline the key details to share with slewing ring bearing manufacturers when seeking application assistance.

Unveiling the Wonders of SlimPro Thin Section Bearings: Features and Benefits

Thin section bearings, also known as slim bearings or thin-walled bearings, have become indispensable components in various industries due to their unique design and remarkable performance. In this blog, we'll explore the features and benefits of thin section bearings, shedding light on why they are the preferred choice for applications where space, weight, and precision matter.

Topics: slewing ring bearing

Understanding Load Capacity and Axial Stiffness in Slewing Ring Bearings

Slewing ring bearings are large, specialized bearings used to support heavy loads and provide axial stiffness in applications such as cranes, excavators, wind turbines, and other heavy machinery. Understanding load capacity and axial stiffness is important when selecting and designing slewing ring bearings for specific applications.

Load capacity refers to the maximum weight that a slewing ring bearing can support without deformation or failure. Load capacity is determined by factors such as the size of the bearing, the materials used, and the design of the raceways and rolling elements. Slewing ring bearings can support both radial and axial loads, as well as moment loads that combine radial and axial forces. It is important to carefully calculate the expected loads in an application to ensure that the selected slewing ring bearing can safely support the weight.

Axial stiffness, on the other hand, refers to the resistance of a slewing ring bearing to axial deflection or bending. Axial stiffness is important in applications where precise positioning and stability are required, such as in machine tools or robotics. Axial stiffness is influenced by factors such as the number and size of the rolling elements, the raceway geometry, and the materials used. Higher axial stiffness results in less deflection and better control over the load, but can also increase stress on the bearing and lead to increased wear and fatigue.

When selecting and designing slewing ring bearings, it is important to balance load capacity and axial stiffness to ensure that the bearing can safely support the weight and maintain stability and precision in the application. Other factors to consider include operating speed, temperature, lubrication, and maintenance requirements. Consulting with a bearing manufacturer or engineer can help ensure that the right slewing ring bearing is selected and designed for a specific application.

Common Slewing Ring Bearing Failures

Slewing ring bearings are critical components used in a wide range of industrial and heavy-duty applications. These bearings can support axial, radial, and moment loads, making them suitable for applications such as cranes, excavators, wind turbines, and more. However, like any other mechanical component, slewing ring bearings are also prone to failure, which can lead to costly downtime, equipment damage, and safety hazards.

In this blog, we will discuss the most common slewing ring bearing failures and their causes.

Installation and Maintenance Best Practices for Slewing Ring Bearings

Slewing ring bearings are critical components in heavy equipment, such as cranes, excavators, and wind turbines. Proper installation and maintenance of these bearings can significantly extend their lifespan and improve overall equipment performance. Here are some best practices to consider:

The Advantages of Slewing Ring Bearings over Other Bearing Types

Slewing ring bearings, also known as turntable bearings or slewing bearings, are a type of rolling-element bearing designed to handle axial, radial, and moment loads simultaneously. Compared to other bearing types, slewing ring bearings offer several advantages, including:

How the Right Packaging Can Ensure Industrial Product Quality

No matter how great the product you’re ordering is, if it isn’t properly packaged, it’s most likely going to be rendered ineffective or even useless to your business. Product packaging is so much more than just aesthetics or a cog in the process of getting a product from point A to point B.

How an Effective Stocking Program Can Save You Money

Without proper inventory management, your business is likely wasting a lot of money.

5 Things You Need to Know About Slew Drives

Topics: slew drive, slewing drive

Subscribe Here!

Recent Posts

Case Study: SlewPro Partnership Saves Time & Money

When Wolf Robotics needed a quick turnaround on a new slewing bearing for a special project in 2017, SlewPro was the only company able to meet the time and specification requirements. The project met all requirements and was on budget, earning more trust from Wolf Robotics’ engineering team.