- Resources

- Case Studies

- Tug Boat Drive Shaft

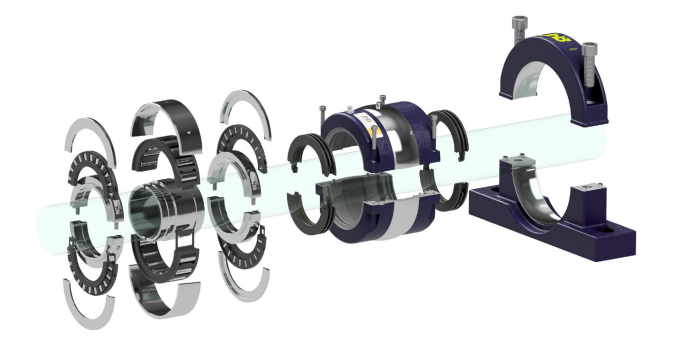

MARINE DRIVE SHAFTS SUPPORT BEARINGS CONVERSION FROM SPHERICAL BEARINGS TO JHB SPLIT ROLLER BEARING

A customer who operates six tugboats, each with twin drive shafts for Plummer block spherical bearings with a shaft sleeve adapter, needed new bearings for the vessels’ drive shafts. John Handley Bearings’ (JHB) split roller bearings delivered immediate benefits.

The Challenge

It took the customer between two and three days to remove the shaft and replace the bearings and realign the shaft. They were having issues with the housing seal plates which, when worn, tend to drag on the shaft and rotate in the housings. This condition eventually causes grooving on the shafts and, when bad enough, will start to resonate, which in turn accelerates wear.

The Solution

JHB, a bearings specialist and leading distributor to some of the world’s leading manufacturers, now offers through Potesta & Company in North America, its high-capacity split roller bearings to replace spherical roller bearings in hard-to-reach propulsion shaft positions on workboats, support vessels, tugs and many other marine applications.

For this application, the solution was to replace the spherical roller bearing with a JHB split cartridge and bearing assembly. The package fit into the existing housing. JHB also designed and 3D printed a new style replacement seal for the housing, moving the sealing surface further along the shaft, past the damaged shaft area.

The Results

By using JHB split bearings in the existing housings, the customer saw numerous benefits. The quick fix was a very cost-effective way to return the vessel back into service, as installation time for all 10 bearings was three hours.

Cost savings for the customer was two days in port for the tug, which is significant, and the boat didn’t have to be pulled from the water. The drive shafts didn’t need to be removed either.

About Potesta & Company

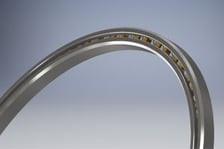

Building on the success of its SlewPro and Rhino Gear brands, the JHB split bearings that Potesta & Company offers are designed to solve your most demanding bearing challenges and deliver immediate benefits, including reduced downtime and increased capacities.

Since entering the market in 2012, Potesta & Company has gained the confidence and trust of manufacturers across North America—from very small to very large—by exceeding their expectations for quality products, responsive service and expert support.

When you work with Potesta & Company, you’ll receive more than a bearing manufacturer. You’ll get a business partner that is willing to understand your application and ensure you have the manufactured components required to complete your projects on time and within budget.

PRODUCTS

CONTACT SLEWPRO

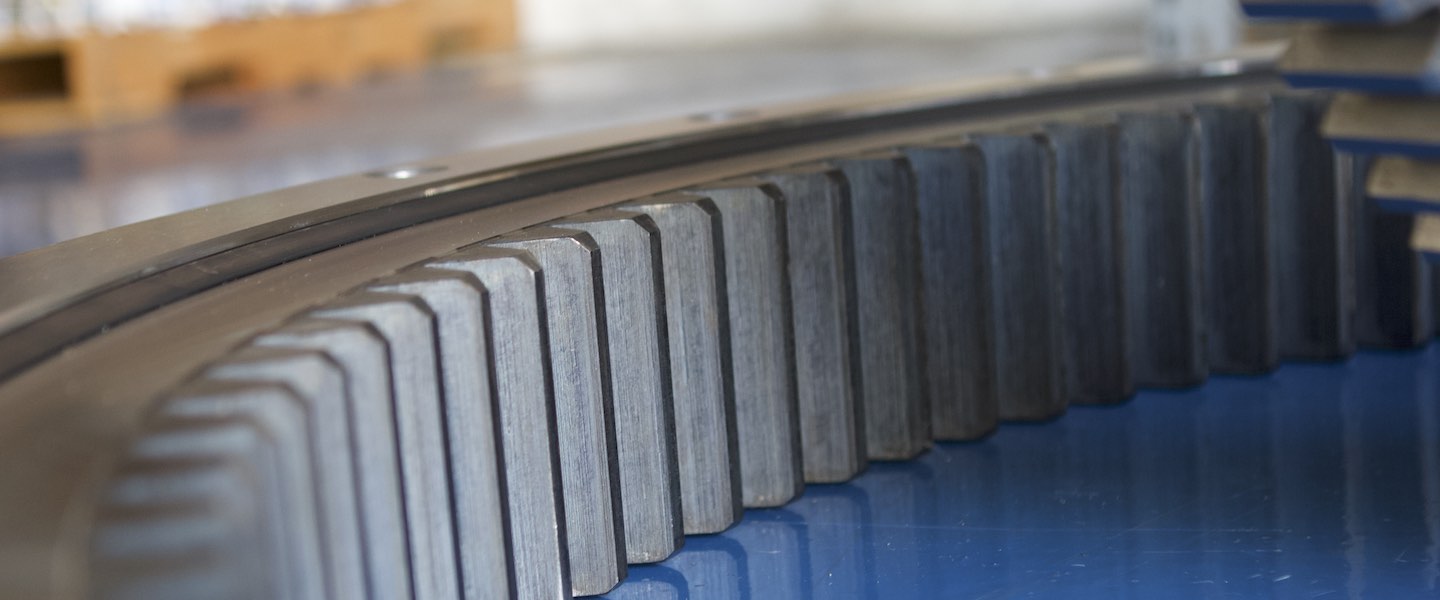

Looking for a slewing ring supplier that can provide you with a custom design as well as quick turnaround on specs and quality throughout? Since 2012, SlewPro has gained the confidence and trust of manufacturers across North America by exceeding their expectations for quality products, responsive service and expert support.

Our team of highly technical personnel offers high-quality slewing ring bearings and custom gears, from turntable bearings to helical gears to spur gears. Whatever your needs, we ensure you have the precision-crafted manufactured components required to complete your project on time and within your budget. If you have additional questions or want to learn more about how we can partner with you, contact us by filling out the form.