GEAR CAPABILITIES

The Rhino Gear team works with a wide variety of small- and mid-sized OEM manufacturers from a number of industries to provide the reliable gearing solutions that keep operations running smoothly.

The Rhino Gear team works with a wide variety of small- and mid-sized OEM manufacturers from a number of industries to provide the reliable gearing solutions that keep operations running smoothly.

General Machining Gear Manufacturing Capabilities

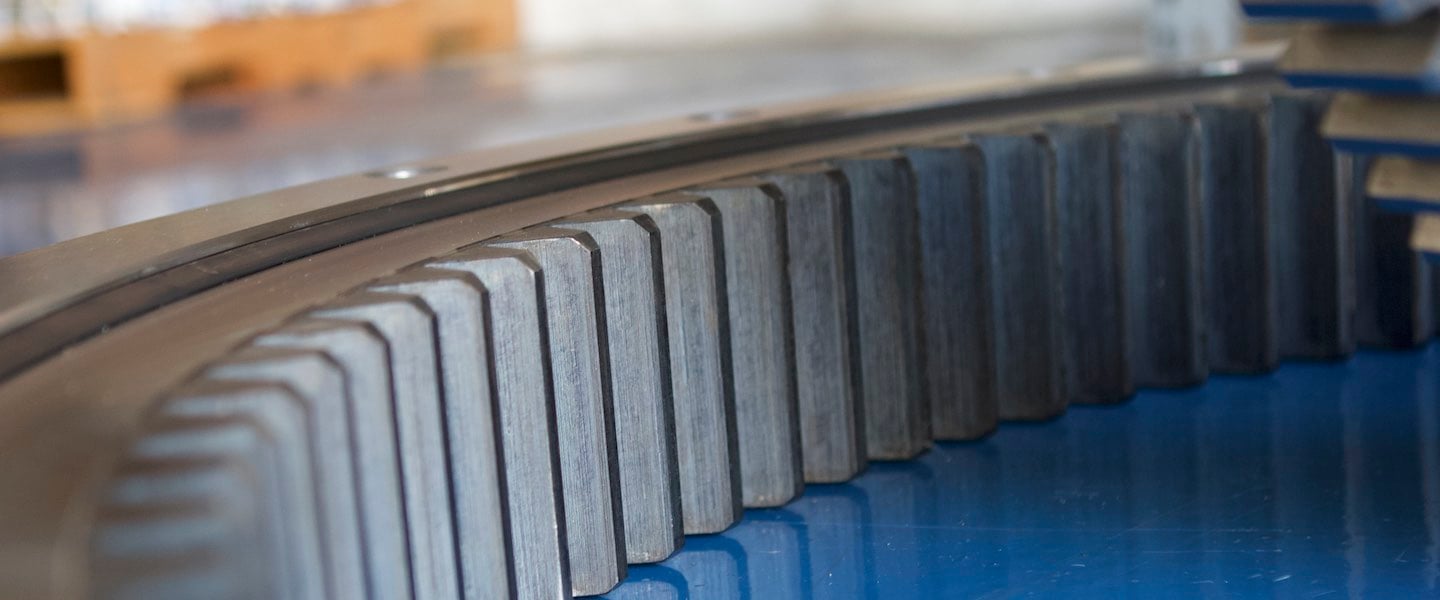

Rhino gears are made in a full-service custom shop that produces custom gears, helical gears, spur gears, internal spur gears, splines, sprockets and pulleys, worms and worm gears, shafts, pinions and other custom machined parts. Our general machining capabilities include:

- Milling

- Drilling

- Turning

- Broaching

Secondary Operations Gear Capabilities

Our team can execute special requests and repairs to ensure operations keep operating and earning money. Rhino Gear experts can also provide:

- Heat treating

- Induction hardening

- Flame hardening

- Nitride machining

- Plating

- An array of grinding services (OD, ID, face, tooth profile and more)

Reverse Engineering Gear Capabilities

We have an in-house engineering team that can conduct reverse engineering from sample parts and assemblies. Using the latest CAD 2D and 3D software, our experts meet the standards OEM manufacturers require. We back our efforts with inspection technologies, including FARO Arm and Maag inspections.

Case Study: SlewPro Partnership Saves Time & Money

When Wolf Robotics needed a quick turnaround on a new slewing bearing for a special project in 2017, SlewPro was the only company able to meet the time and specification requirements. The project met all requirements and was on budget, earning more trust from Wolf Robotics’ engineering team.