- Resources

- Case Studies

- InterTronic Solutions Antenna Systems

“Richard [Potesta] really knows his stuff. It was very useful to have that extra expertise when choosing this part. It was a very critical part of our system.”

– Stephen Shield, Chief Engineer at InterTronic Solutions

The Challenge

InterTronic Solutions, a manufacturer of high-performance antenna systems, had the opportunity to develop a 12-meter system and needed slew bearings to help with the rotation of the reflector.

The company used slew bearings from other manufacturers in the past for smaller antenna systems, but when it was trying to find suppliers for the larger system, InterTronic Solutions discovered that a lot of these companies were tied up doing wind turbine projects. Even more frustrating was that their products were incredibly expensive, and their lead times were very long.

A Custom Manufacturer When It Was Needed Most

Unless you’re ordering 100-plus units, most manufacturers won’t take the time to work with you to design a bearing that fits your exact needs. Instead, you’ll receive a bearing that’s been pre-engineered and mass-produced.

A custom manufacturer has the capability to build an equivalent bearing for your product at a lower price point—while offering a higher level of service than their catalog counterparts. With custom manufacturers, the exact needs of each customer come first.

That’s what InterTronic Solutions found in Potesta & Company.

“They were able to build us anything we wanted,” said Stephen Shield, chief engineer at InterTronic Solutions. “They were able to build us the exact bearing that we needed, the right size, their lead times were a lot better and the pricing was a lot more competitive.”

While the other manufacturers had six- to nine-month lead times, according to Shield, Potesta & Company's lead time was only four to five months.

When InterTronic Solutions reached out to Potesta & Company, Shield added that the company was “very responsive” and “submitted drawings right away.”

“Richard [Potesta] really knows his stuff,” Shield said. “It was very useful to have that extra expertise when choosing this part. It was a very critical part of our system.

“It’s not a part that’s easily changeable; it’s probably the hardest part to replace in the system. If it has to be done, it requires dismantling the whole thing, so we really needed something that would last the lifetime of the system.”

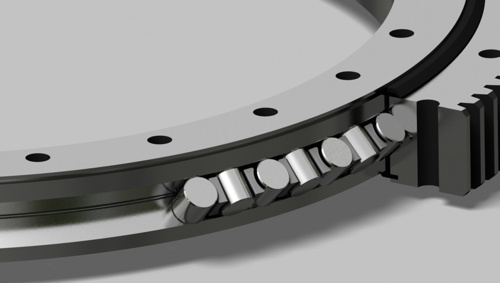

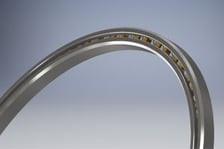

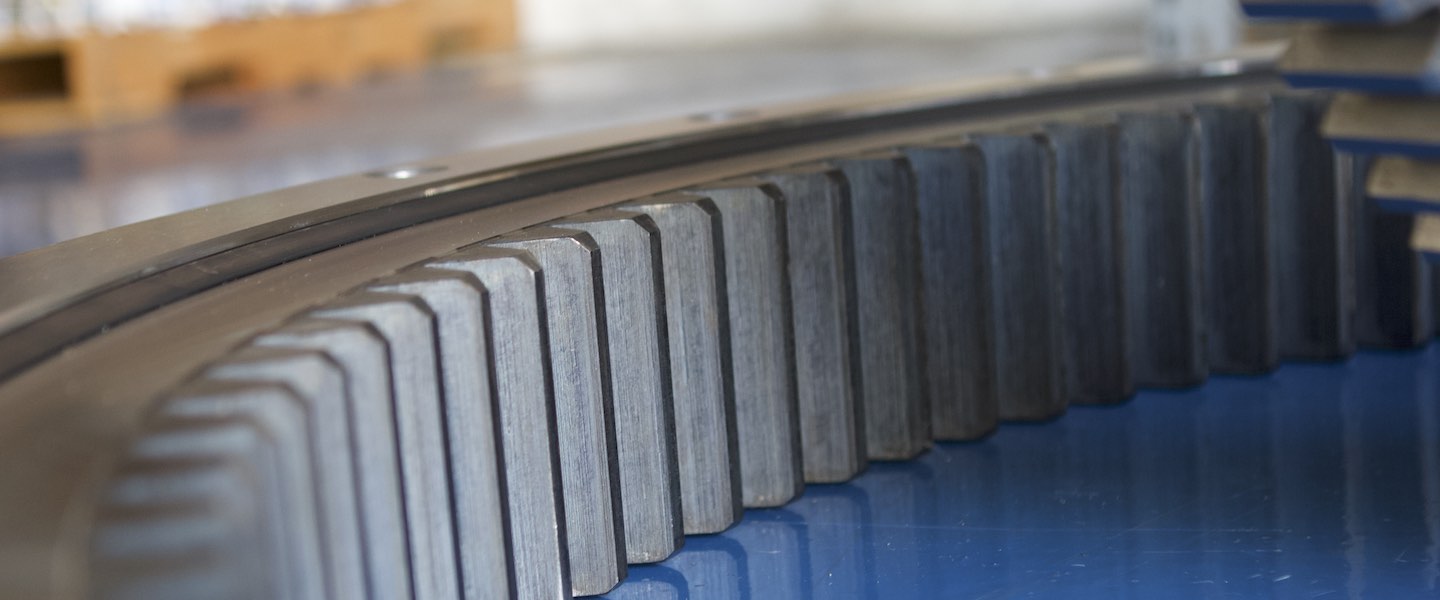

The main bearing used was the SlewPro 50 Series internally geared cross roller bearing, which is designed for high stiffness and available in a variety of mounting configurations. Potesta & Company not only supplied the primary bearing but the segment gears, shafts and pinions used within the system as well.

What Made Potesta & Company a Different Slew Ring Bearings Manufacturer

Flexibility was the biggest differentiator for InterTronic Solutions.

“They really are flexible with almost anything, so we’re not constrained in our design,” Shield said. “Any size reflector we want to build, I know [Potesta & Company] can build me a bearing that will match. I don’t have to go with the catalog part. Not to be constrained like that makes the design process a lot easier.”

About Potesta & Company

Since entering the market in 2012, Potesta & Company has gained the confidence and trust of manufacturers across North America—from very small to very large—by exceeding their expectations for quality products, responsive service and expert support.

When you work with Potesta & Company, you’ll receive more than a bearing manufacturer. You’ll get a business partner that’s willing to understand your application and ensure you have the manufactured components required to complete your projects on time and within budget.

PRODUCTS

CONTACT SLEWPRO

Looking for a slewing ring supplier that can provide you with a custom design as well as quick turnaround on specs and quality throughout? Since 2012, SlewPro has gained the confidence and trust of manufacturers across North America by exceeding their expectations for quality products, responsive service and expert support.

Our team of highly technical personnel offers high-quality slewing ring bearings and custom gears, from turntable bearings to helical gears to spur gears. Whatever your needs, we ensure you have the precision-crafted manufactured components required to complete your project on time and within your budget. If you have additional questions or want to learn more about how we can partner with you, contact us by filling out the form.