- Resources

- Case Studies

- Automated Conveyors

SLEWPRO BRINGS CUSTOMER SERVICE & EXPERTISE TO SUPPORT LOOP BELT INDUSTRIES’ MOVE INTO FRACKING

Lacking existing parts to work with, Joseph Gallione, owner/partner at Loop Belt Industries, looked to existing suppliers to fill his manufacturing needs but was unable to find a company capable of meeting both his time constraints and quality demands.

"From start to finish, SlewPro has lived up to its promises on delivery and quality and helped keep our new machine development on schedule. I am sure to count on SlewPro again for our future slewing bearing needs."

– Joseph Gallione

Loop Belt Finds Opportunities in Oil

The experts at Loop Belt, a Schwing America company, represent a combined 85 years of experience in delivering construction and automated conveyor solutions. The company’s current roster of truck-mounted telescopic conveyor systems includes the LB-33T4-20, with a conveyor reach of 107’ 1”, and the LB-40T5-20 and TTLB-40T5-20, each with a conveyor reach of 129’ 9”.

Traditional areas of operation for Loop Belt involve concrete construction for residential foundations and heavy civil projects. Along with the ability to rapidly convey concrete, Loop Belt’s conveyor systems can also efficiently move large quantities of aggregate. It was the last capability that drew the attention of the fracking industry.

Hydraulic fracturing, more commonly known as fracking, represents an industry with large growth potential. Investments in fracking and other methods of domestic oil production have resulted in reduced oil imports to the United States. Currently, the U.S. only imports 40 percent of its crude oil needs, which is good for both the economy and national security. Fracking requires extraction teams to inject vast quantities of sand into the earth to drive oil to the surface. Loop Belt’s conveyor systems seemed an obvious choice to help the fracking teams achieve their goals, but the switch from pouring concrete to delivering sand required redesigning some elements of the conveyor system.

Greater Flexibility

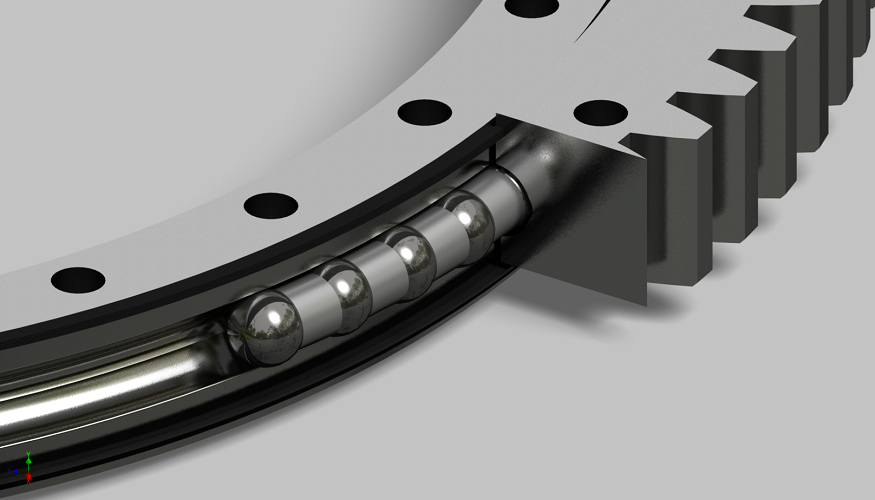

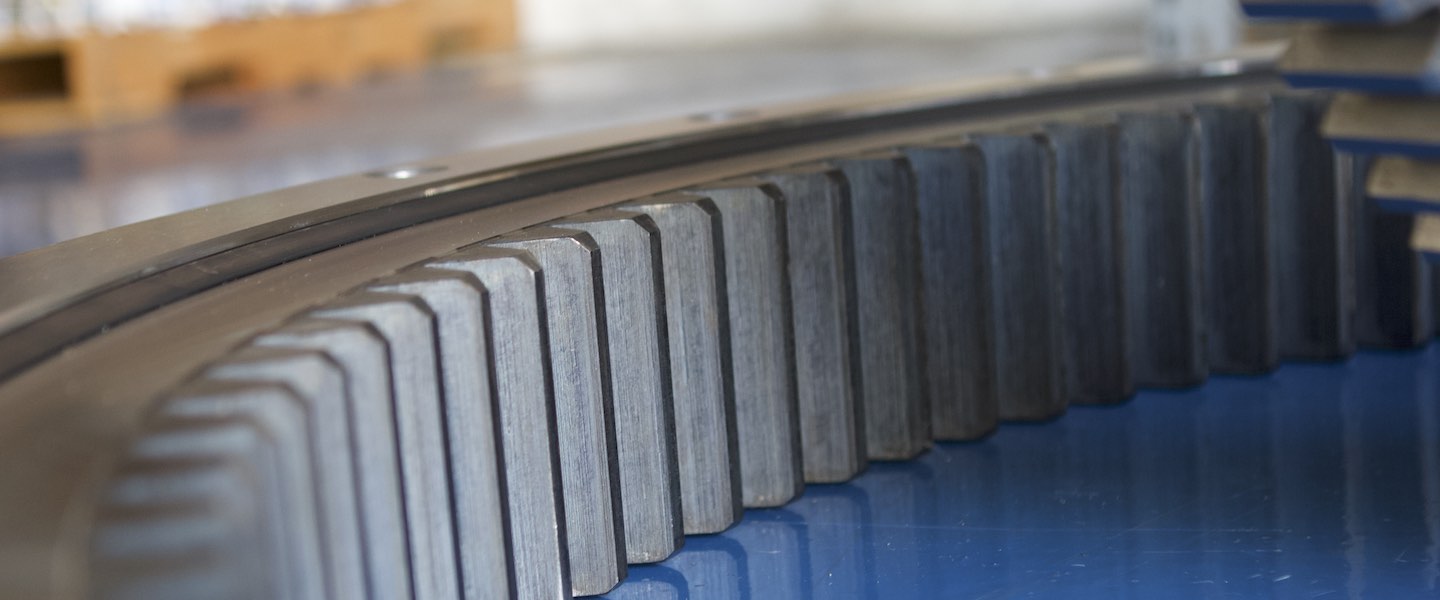

The slewing ring bearing manufactured by SlewPro is required to maintain the integrity of the system and allow for 360° range of operation. Part of the redesign required the introduction of two externally geared slewing ring bearings and pinions: one for the main turret holding up the Loop Belt conveyor and a smaller one for the feed conveyor turret. The bearings were required to hold the majority of the weight of the conveyor system for extended periods and remain in operation for years at a time.

Commitment to Quality

SlewPro was able to assist with the design and development of the new parts, and reduced manufacturing time by over half, from 22 weeks to SlewPro’s standard 10- to 12-week delivery time. The quality of the slewing ring bearings is backed by SlewPro’s quality management, which includes ISO 2008 standards.

“When we needed a large diameter, heavy-duty slewing bearing for a new telescopic conveyor to be introduced in the construction equipment market, I first looked at the well-known suppliers of these bearings,” Gallione said. “However, I found these suppliers could not meet the delivery requirements I needed to complete this new machine. My search for another supplier led me to SlewPro. Richard Potesta was very responsive and professional in understanding my slewing bearing needs and came through with an exceptionally short 10- to 12-week lead time and very competitive pricing. From start to finish, SlewPro has lived up to its promises on delivery and quality and helped keep our new machine development on schedule.”

Products

CONTACT SLEWPRO

Looking for a slewing ring supplier that can provide you with a custom design as well as quick turnaround on specs and quality throughout? Since 2012, SlewPro has gained the confidence and trust of manufacturers across North America by exceeding their expectations for quality products, responsive service and expert support.

Our team of highly technical personnel offers high-quality slewing ring bearings and custom gears, from turntable bearings to helical gears to spur gears. Whatever your needs, we ensure you have the precision-crafted manufactured components required to complete your project on time and within your budget. If you have additional questions or want to learn more about how we can partner with you, contact us by filling out the form.