- Products

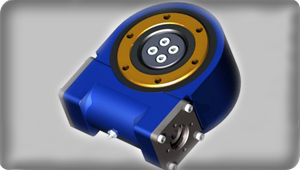

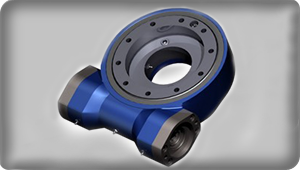

- Slewing Drives

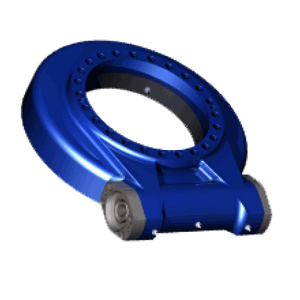

Slew Drives

Heavy-Duty Slew Drives for Almost Any Application

Potesta & Company’s SlewPro line features a myriad of slew drives for almost any application. A slew drive is designed to handle radial or axial loads using high rotational torque. Equipment for mining, construction, metalworking and other applications that require unrelenting strength combined with faultless precision use slewing technology for safety and accuracy.

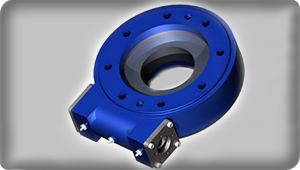

Our slew drives can cross over all major brands for an exact fit, and with tilting moment capacity of 1,475 foot-pounds. to 200,000 foot-pounds, you’re sure to find a perfect fit. All SlewPro slew drives are modular and come with a variety of options, including:

- Single worm drives

- Double worm drives

- Hydraulic motors

- Electric motors

- Pneumatic motors

- Encoders

- Brakes

- Tracking precision to 0 degrees

- Open chassis

- Enclosed chassis

Understanding the physics, types, functions and features of a slew drive is crucial to successful applications and optimal performance. Here are five things you need to know about slew drives.

Can’t find a slew drive that fits your needs? Our team of engineers can design a slew drive unique to your application. For more information on specific slew drives, click on the links to get started.

To learn more about our products, including slew drive price, request a quote or contact us directly.

PRODUCTS

.jpg?width=1900&height=1267&name=SlewPro%20Bearings%20Blog%20image%20(1).jpg)

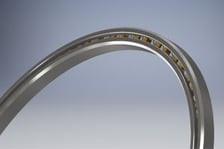

Case Study: SlewPro Partnership Saves Time & Money

When Wolf Robotics needed a quick turnaround on a new slewing bearing for a special project in 2017, SlewPro was the only company able to meet the time and specification requirements. The project met all requirements and was on budget, earning more trust from Wolf Robotics’ engineering team.