RHINO GEAR HELICAL GEARS

Rhino Gear makes a wide variety of custom and off-the-shelf helical gears that provide advantages in all kinds of applications.

Rhino Gear makes a wide variety of custom and off-the-shelf helical gears that provide advantages in all kinds of applications.

The use of helical gears is generally needed when the application involves high speeds, larger power transmission or where noise reduction is important, which is why most car transmissions use them.

Helical gears have teeth that are set at an angle. They're very similar to spur gears, except the teeth of a helical gear are cut at an angle to the axis or hole. These teeth typically engage more slowly and smoothly than other types of gears used for similar applications because the load is transferred uniformly and gradually.

This results in superior performance, reduced noise and vibration.

When used on parallel shafts, helical gears are like spur gears, but generally provide a stronger, smoother running gear train. Besides smoother motion, higher speed capability and less noise, another advantage that helical gears provide over spur gears is the ability to be used with either parallel or non-parallel (crossed) shafts. Helical gears with parallel shafts require the same helix angle, but opposite hands (i.e., right-handed teeth vs. left-handed teeth). Helical gears are made in both right- and left-hand configurations.

Rhino Gear Helical Gear Manufacturing Capabilities

When deciding which type of gear is best for your project, there are a number of important measurements that should be considered, including:

- Pitch diameter range: ½” to 50”

- Diametric pitch range: 1½ to 64 (17–0.4 module)

- Face width range: ¼” to 24”

Our team is ready to assist you through every stage of the gear manufacturing process to ensure we find a solution to meet your needs. Contact us today or request a quote.

PRODUCTS

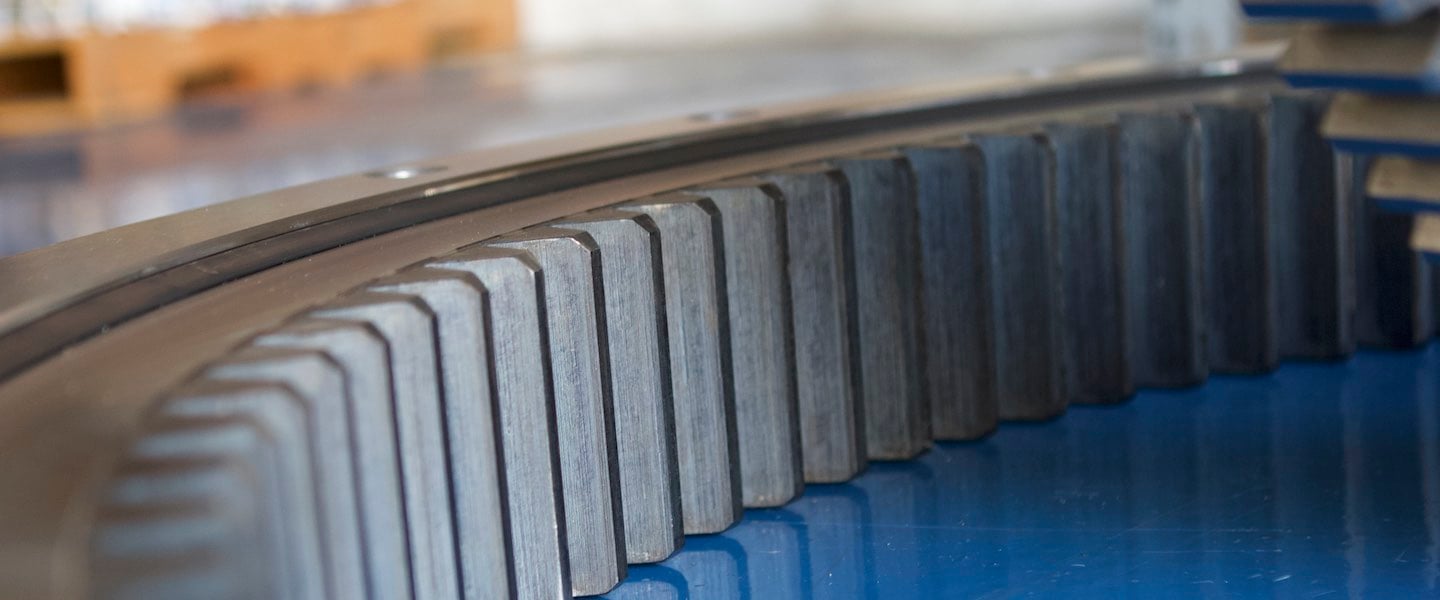

Case Study: SlewPro Partnership Saves Time & Money

When Wolf Robotics needed a quick turnaround on a new slewing bearing for a special project in 2017, SlewPro was the only company able to meet the time and specification requirements. The project met all requirements and was on budget, earning more trust from Wolf Robotics’ engineering team.